Solving safety & labor shortages via tech

Due to its physical requirements, construction has resisted automation longer than almost every major industry. That trend is ending. Humanoid robots, armed with AI, computer vision, and tougher materials, are stepping onto job sites and changing the economics of how we build. The catalysts are plain: unpredictable terrain that once defeated machines is now navigable; unions focused on safety are open to augmentation; and capital is searching for durable productivity gains instead of short-term fixes.

This convergence of technological maturity and economic necessity is not coincidental. It reflects decades of incremental innovation across robotics, materials science, and artificial intelligence.

The pressure is real. In 2023, 5,283 fatal work injuries were recorded in the U.S., with construction taking a disproportionate share. In fact, the U.S. Bureau of Labor Statistics states that “construction had the most fatalities (1,075)among all industry sectors in 2023.” These statistics do not only represent tragic losses of life, but they also carry broader consequences for companies and economies. Each incident translates into project delays, legal liabilities, rising insurance premiums, and reputational damage for contractors.

In addition to these dangers, labor shortages have become chronic. Part of this is because young people are continually funnelled towards college instead of trades, the existing trade workforce is aging, and there are issues with low pay and high overheads in the industry. Cost overruns push big infrastructure from “ambitious” to “uneconomical.” In fact, it’s been recently estimated that the U.S. construction industry faces a shortage of over half a million workers in 2024 alone, a gap that is forcing firms to rethink workflows and accelerate the adoption of robotics to sustain project delivery. The question is no longer whether robotics will rewire construction; it’s who captures the value as this market accelerates.

This research will look at the different ways in which humanoid robots will affect the industry, including:

- Robots on the Job: How humanoid robotics affect core construction activities

- Eyes Everywhere: The rise of AI-enabled inspection and quality control

- Supercharged Safety: Worker augmentation and injury reduction

- Workflow Wonders: Operational efficiency and automation

- Obstacle Course: Challenges and barriers to adoption

- Ethics, Liability & Trust: Building confidence in humanoid construction robotics

- The Human Equation: Labor impacts and workforce dynamics

- After the Rubble: Future opportunities in construction robotics

- Playing to Win: Strategic implications for investors and companies

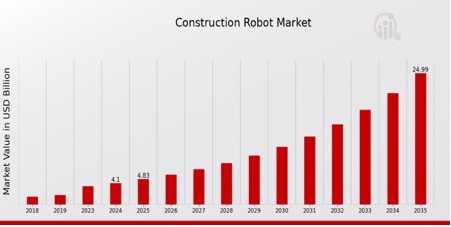

This transformation is inevitable. The market for construction robots is expected to scale from $4.8 billion in 2025 to $25 billion by 2035, as you can see below in Figure 1:

Figure 1: Market Research Future. Construction Robot Market.

The primary gain from technology adoption in the construction market will go to companies that convert messy, outdoor reality into repeatable, safe, and data-rich workflows. Early movers that prove ROI in specific construction tasks will extend into platforms. Everyone else will likely rent from them.

Robots on the Job: Humanoid Robotics in Core Construction Activities

One of the primary areas to be affected in the industry is core construction activities. These include site preparation, planning, foundation work, electrical and plumbing, and inspection tasks. Having human workers for all these tasks can expose people to danger and can also be costly in several ways.

For example, the costs of construction extend well beyond wages. They compound through safety gear, insurance, and workers’ compensation for the unfortunately frequent injuries in the sector. Humanoids change this equation. They lift consistently from hour one to hour twelve and are not at risk of harm in the same way that people are. They can also be designed to exceed human capacity while maintaining the dexterity needed for precision placement: exactly where human fatigue creates errors. Beyond physical ability, humanoids can integrate directly with Building Information Modeling (BIM) systems to execute plans with machine-level precision. Instead of interpreting paper blueprints, they can translate digital schematics into action, reducing miscommunication between architects, engineers, and workers.

One example of a humanoid already being tested in construction is the HRP-5P robot, made by AIST, Japan’s National Institute of Advanced Industrial Science and Technology. The HRP-5P robot is designed to perform tasks autonomously in dangerous settings, and has stereo vision, LiDAR, and 3D sensors. It can identify objects and operate autonomously, doing tasks like assembling drywall, installing boards, and locating elevators. You can see an image of the HRP-5P robot in Figure 2 below:

Figure 2. AIST. HRP-5P appearance (left) and HRP-5P carrying an approx. 13 kg board (right).

Another example is the Apollo robot from Apptronic, which is designed for manufacturing and is planned to extend into construction and other sectors. Apptronic recently announced a strategic collaboration with Jabil, a manufacturing and supply chain provider, to test and improve Apollo further. Apollo is part of a new wave of humanoids engineered for scalable production, with Apptronic targeting tens of thousands of units within the decade. This is a clear sign that humanoids are moving beyond research prototypes into commercially viable platforms. Other non-humanoid robots like Spot from Boston Dynamics, Built Robotics’ pile driving and trench-digging robots, and Baubot (a robot with a humanoid arm) are also being used on construction sites for tasks such as mapping sites with real-time updates, bricklaying, plastering, and tiling.

Figure 3: Baubot

One of the difficulties with construction robots in practice is adapting them to the unpredictability of worksites, which has slowed their introduction. Unlike controlled manufacturing environments, construction sites are messy and constantly changing. Mud, debris, uneven terrain, and shifting layouts create obstacles that robots must navigate in real time. Some robots (such as Spot) have greater mobility and can adjust well, while others need specific conditions to be able to perform effectively. Nonetheless, their presence is increasing, and further improvements are closing these gaps.

When you pair humanoids with additive manufacturing, the possibilities increase. Stationary 3D printers force projects to orbit the machine. Mobile, humanoid-mounted printing shifts this: robots will be able to navigate complex sites, print where the work is, and keep pace with changing conditions. One study notes that these types of robots “could additively manufacture replacement parts on-site, repair cracks, or create customised reinforcements”. The benefit compounds in modular construction, where parallel assembly can speed up work significantly. AI-enabled vision can measure components in real time and adjust tolerances, so modules combine cleanly, replacing rework with assemblies that are correct the first time.

Another key factor is that progress, weather, traffic, and temporary obstacles create a living, shifting environment, which requires certain skills from construction robots. Advanced humanoids can use a combination of LiDAR, computer vision, and inertial measurement to continuously remap the site and move safely around people and machines. This adaptability is not a nice-to-have; it’s a requirement for demolition, high-rise logistics, and confined-space work where the risk to humans is the highest.

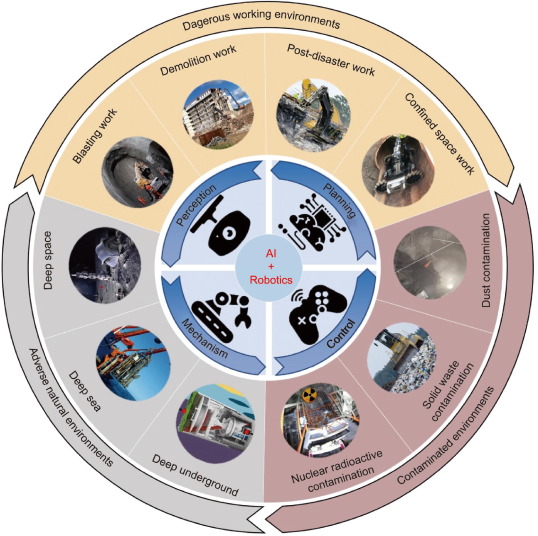

In Figure 4 below, you can see some of the potential complex environments in which robots can already work and will be able to work, including demolition, confined-space work, blasting work, deep underground and deep sea, and contaminated environments:

Figure 4: Science Direct. Typical examples and key technologies of construction robotics in extreme environments

These opportunities from humanoid robots, combined with AI technologies, can significantly increase the potential environments in which construction can be carried out safely. Robots that can operate in these ways will also significantly alter the cost of such projects or operations, as both labor costs and insurance coverage costs decrease. The insurance market itself is beginning to reflect this shift, with insurers exploring reduced premiums for projects employing robotics, citing both lower injury exposure and improved risk predictability.

Eyes Everywhere: AI-Enabled Inspection and Quality Control

Another key area of improvement with humanoid construction robots is AI-enablement, and the benefits it offers. This is most prominent in quality control and inspection processes. This is because traditional inspection is periodic and reactive. Problems surface after work is buried, triggering rework cycles that can create significant increases to project costs and push delivery dates out. AI inspection robots can prevent this.

AI-enabled inspection robots shift quality assurance from a problem into an embedded process. With continuous data collection and machine learning algorithms trained on millions of inspection points, these robots can identify deviations invisible to the human eye. For example, a robot could detect microfractures in concrete or subtle misalignments in structural steel long before they become critical faults. This early detection not only saves costs but also enhances safety by ensuring structural integrity from the outset.

One example of an AI-enabled inspection robot is from Field AI, which uses robots like Boston Dynamics’ Spot robot, to traverse construction sites and carry out automatic site inspection. At the 2025 Hannover Messe, a collaboration between Accenture, Schaeffler, Nvidia, and Microsoft also showcased a humanoid inspection robot that could navigate around a site and human workers, identify inspection targets, make autonomous decisions, and use digital twins as well as cloud-connected intelligence. You can see the robot in Figure 5 below:

Figure 5: Metrology. Humanoid robots can integrate into production environments to support precision inspection, maintenance, and adaptive quality control

One study from 2024 notes that collaborative inspection robots “bring precision, consistency, and real-time data analysis to quality control processes, enabling more thorough inspections and defect detection.” Another study from 2025 examined how AI-driven quality control could impact manufacturing and construction, finding that “AI-driven quality control enhances efficiency, reduces human error, and lowers operational costs in both sectors.”

With computer vision and LiDAR, AI-enabled robots can run continuous quality control, flagging issues as they appear, not weeks later. Correcting a structural defect in-process can cost much less than fixing it later. Across complex projects, this is the difference between budget shock and budget discipline.

Continuous monitoring also manufactures data assets. Digital twins from construction projects become baselines for long-term structural health monitoring and predictive maintenance. For builders and investors, that creates recurring revenue beyond the build: service contracts, compliance automation, and portfolio-level risk management. Interest in quality control robots is also rising, with research on these tasks increasing over time, although not yet in the construction sector. In manufacturing, however, research on similar tasks is a hot topic, as you can see in Figure 6 below:

Figure 6. T & F Online. Number of publications related to quality control in manufacturing and robotics

Even on day one, automated quality control documentation reduces issues from human error and satisfies regulators who increasingly expect machine-grade records. The Field AI robots mentioned above can also help to standardize data collection and analysis, which helps to quickly determine risks, as well as improve accuracy and efficiency.

The Atlas robot, already showcased by Boston Dynamics in a construction site, uses a “method called predictive control” in which it collects significant data from the site, which can be used for analysis later. You can see the Atlas robot below in Figure 7:

Figure 7. Boston.com. The Atlas robot in action

Boston Dynamics and Toyota Research Institute have also recently collaborated to power the Atlas robot with an LLM, used for general purpose tasks, including walking, crouching, lifting, packing, sorting, and organizing tasks. The AI-enablement can significantly improve data collection for tasks, and therefore quality control and data analysis.

Supercharged Safety: Worker Augmentation and Safety

Full autonomy isn’t the only way to create huge improvements in the sector. Augmentation through commercial exoskeletons is another major area of interest, as they reduce physical strain on workers. Back and arm support exoskeletons are the two main areas that exoskeletons focus on. There are also lower-body support exoskeletons for kneeling and climbing. The HILTI EXO-S is one example of an exoskeleton for shoulder and neck support, shown in Figure 8 below:

Figure 8. HILTI. HILTI EXO-S

Augmentation also raises output. Workers equipped with exoskeletons sustain performance across long shifts. One study from 2025 found that “exoskeleton-assisted work led to significant productivity improvements, particularly in high-intensity tasks, with productivity gains of up to 59.5%.” Hilti has further emphasized that these systems are not just for productivity but also for extending the working lives of older workers, a crucial benefit in an industry struggling with an aging workforce and chronic labor shortages.

The safety and output improvements are also not the only benefits; using exoskeletons lowers insurance costs, simplifies compliance, and allows work to be carried out in environments previously deemed too risky.

Safety issues can also be alleviated with fully autonomous robots, not just exoskeletons. This is particularly clear in relation to post-disaster rebuilding, where robots can enter compromised structures, stabilize hazards, and accelerate recovery. One example is a collaboration between ABB Robotics and Cosmic Buildings, which deployed rebuilding robots after the Pacific Palisades fires. This use of AI-enabled robotics for post-disaster reconstruction is emerging as a niche market, with insurers and governments willing to subsidize costs in exchange for faster recovery and reduced human exposure to hazards. Governments and insurers will pay premiums for faster, safer reconstruction, making disaster-response robotics a high-impact, economically rational niche.

Workflow Wonders: Operational Efficiency in Construction

Automation also significantly improves coordination and operational flow. Humanoids and other robots excel at repeating tasks in a precise manner, including concrete finishing, surface prep and component assembly, without the physical limitations of a human worker. Combined with autonomous heavy equipment such as the Built Robotics pile drivers and trench diggers, you get end-to-end workflows where humanoids handle dexterous tasks while machines move earth and material around them.

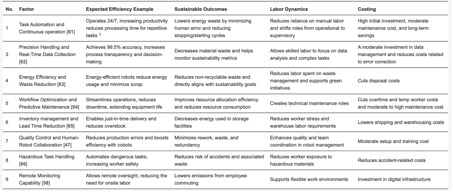

The result is construction that behaves more like manufacturing: predictable timelines, steady quality, optimized resource use, and fewer surprises. One 2025 study looking at the Tesla Optimus humanoid robot found that “humanoid robotic automation in warehouses decreased operating expenses by 15% and improved efficiency by 25%.” Similar humanoid use in construction processes will also have major benefits for efficiency and cost reduction. Some examples of tasks that will become more efficient are outlined in the table in Figure 9 below:

Figure 9. MDPI. Possible impact of humanoids on supply chain efficiency, sustainability, labor dynamics, and costing

The data layer finishes the job. Robots will be able to collect data and transmit it to train machine-learning models that forecast delays days or weeks ahead through predictive analytics. Delays are one of the major issues that the industry faces, whether from poorly-planned projects or unexpected issues, as well as weather impact, supply chain problems, and more. Predictability reshapes bidding as well, as contractors will be able to carry smaller risk premiums, owners can stage and predict subsequent phases with confidence, and suppliers can streamline and better manage their inventory.

Obstacle Course: Challenges and Barriers

The same factors that slow the process of automation in construction, including difficult terrain, unpredictable weather, and constantly changing work environments, are still among the hardest problems for humanoid robots to solve. These environmental challenges are becoming a proving ground for manufacturers. Robots that can maintain stability in rain, snow, or heat waves, while navigating debris and working alongside human crews, will define which companies dominate.

Extreme environment resilience is not just a technical milestone; it is a differentiator that will separate winners from losers in the robotics market. A robot that can function in -10°C snow or in 45°C desert heat expands its utility to global projects, from Canadian mining towns to Middle Eastern megacities. Manufacturers that succeed here will capture international contracts, while those that cannot prove resilience risk being confined to niche, controlled environments. Labor relations are another major challenge. Historically, unions have viewed automation with skepticism, often seeing robots as a threat to job security. However, the conversation is shifting. As safety becomes a top priority, unions are increasingly open to technologies that reduce injuries and extend workers’ careers. The International Union of Operating Engineers has already partnered with Built Robotics to provide training programs for robot-equipped crews, marking a shift from confrontation to collaboration in how unions engage with automation.

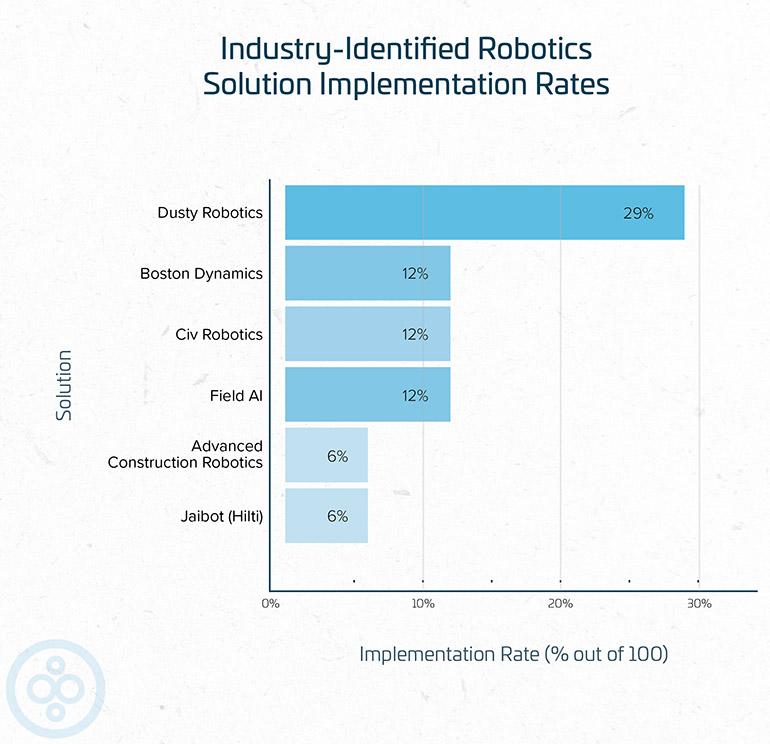

In addition, a 2024 survey found that “nearly two-thirds of the surveyed contractors who use robotics on jobsites are using monitoring and/or service or labor robotics,” and that attitudes towards automation in the industry are warming. The same survey found that robots from Dusty Robotics were the most frequently implemented product, with Boston Dynamics, Civ Robotics, and Field AI following behind at equal rates, as shown in Figure 10 below:

Figure 10. The Robot Report. Dusty Robotics is a leading brand in construction robotics implementation, found the survey

Construction robotics currently operate in a regulatory gray area. While companies must comply with existing ANSI/RIA R15.06 safety requirements for robots and robot systems, OSHA standards and local building codes lack specific provisions for construction robots, leaving early adopters to navigate uncharted regulatory territory. This regulatory vacuum presents a strategic opportunity. Companies that proactively engage with regulators to develop safety guidelines for human-robot interaction aren’t just ensuring compliance; they’re writing the rulebook. As formal standards emerge, these early collaborators will enjoy significant competitive advantages.

History demonstrates the power of regulatory influence. Just as automotive giants shaped crash-test standards to favor their technologies, construction robotics pioneers who establish safety and compliance benchmarks will secure structural market advantages. The firms helping to define today’s standards will be best positioned to meet tomorrow’s requirements. As regulatory frameworks solidify, compliance itself becomes a competitive moat. Companies whose robots achieve multi-jurisdictional certification will access broader markets while creating barriers for competitors still struggling with regulatory approval. In this emerging industry, regulatory engagement isn’t just about risk management; it’s about market positioning.

Cost remains one of the biggest hurdles for smaller firms. Purchasing a humanoid robot outright is expensive, but Robotics-as-a-Service (RaaS) could allow firms to spread costs out over time. This pay-as-you-go approach is already common for autonomous heavy equipment, and humanoid robots may follow the same path, lowering the barrier to entry for mid-sized construction firms.

Integration is a less obvious but equally complex challenge. Construction sites rely on dozens of equipment types, software platforms, and external subcontractors. If humanoid robots cannot seamlessly connect with project management systems, safety expectations, and scheduling software, efficiency gains will be limited.

Ethics, Liability, and Trust: Building Confidence in Humanoid Construction Robotics

As humanoid robots move from pilot programs into daily use, questions of ethics, liability, and trust become unavoidable. Construction sites are high-risk environments, and accidents can carry human, financial, and legal consequences. Unlike in manufacturing, where robots operate in controlled settings, construction introduces open, unpredictable conditions. This raises questions about who bears responsibility when a robot makes an error or causes harm.

Liability is still a gray zone. Should fault lie with the construction firm, the robotics manufacturer, or the software provider when an AI-enabled robot fails? Legal scholars are already debating whether existing occupational health and safety frameworks can stretch to cover autonomous systems, or whether new categories of liability will need to be created.

Trust also extends to workers themselves. For robots to succeed, crews must feel confident working alongside them. Research on human–robot collaboration in construction shows that trust is built not only on performance, but also on transparent communication. Robots that can signal intent, explain actions, or follow predictable patterns are integrated more smoothly into teams. This makes the design of user interfaces, safety protocols, and fail-safes as critical as hardware strength or AI sophistication.

Insurers and regulators are beginning to weigh in. Insurers are piloting new risk models that incorporate robotic safety data into premium calculations, rewarding contractors who deploy robots to reduce injury exposure. Governments, meanwhile, are exploring standards for human-robot interaction, though most remain at an early stage. In Europe and Asia, regulators are moving faster: Japan has already issued guidelines for humanoid safety testing in public settings, while Chinese policymakers frame humanoids as both a productivity tool and a strategic asset under its AI industrial policy.

Construction is an industry where malfunctions can cost lives. Firms that treat ethics and liability as core design features, not afterthoughts, will not only win regulatory approval, but also earn the confidence of insurers, unions, and the workers expected to collaborate with humanoid teammates.

The Human Equation: Impact on Labor and Workforce Dynamics

Robotics is already reshaping construction roles, but not always in the way many people fear. While some repetitive manual tasks may be automated, new jobs are emerging for robot operators, maintenance technicians, and data analysts. These positions often (but not always) pay more than traditional roles, but require new technical skills. For younger workers, this shift could make construction more appealing, as it can become more of a tech-forward job rather than purely physical labor.

Retraining is also a critical part of this transition. Traditional safety courses and trade certifications don’t cover working alongside robots. Instead, training programs are being designed to teach workers how to troubleshoot robotic systems, supervise autonomous machinery, and collaborate effectively in mixed teams. Companies like Built Robotics already run training modules for autonomous heavy equipment, and similar certifications for humanoid robots are likely to follow.

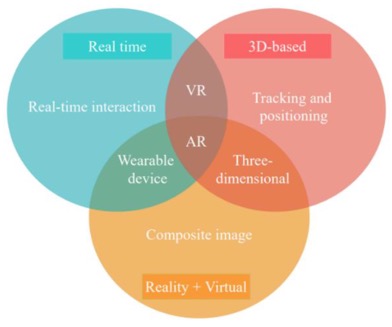

Virtual reality (VR) and augmented reality (AR) tools are also being introduced to speed up this learning curve. These platforms allow workers to practice operating or repairing robots in simulated environments without the risks or costs of a live construction site. Early evidence shows that VR-based training can cut training time by up to 60% while improving retention and safety outcomes.

You can see in Figure 11 below a Venn diagram showing how VR and AR components interact with real time information, highlighting the differences between VR and AR:

Figure 11: MDPI. Three elements of AR

In the long run, firms that embrace robotic integration will be able to recruit more effectively, offering safer and less physically punishing roles. This could help address a looming demographic issue: the construction workforce is aging rapidly, and the US faces a shortage of at least half a million construction workers annually. Robots won’t replace workers outright, but they can make the industry more attractive and sustainable.

After the Rubble: Future Opportunities

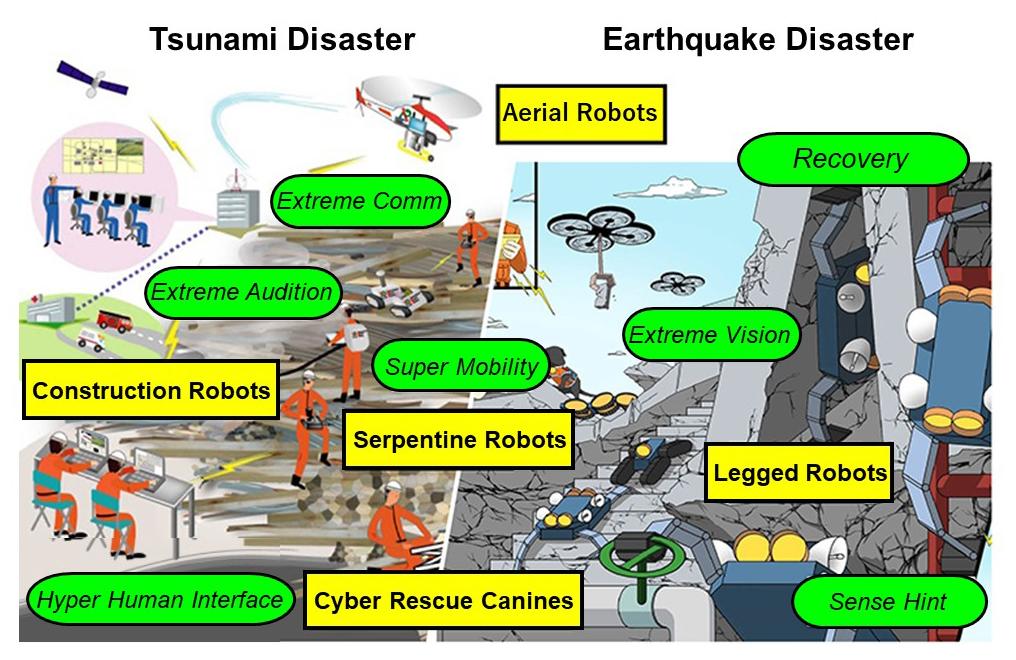

Some of the most promising opportunities for humanoid robots in construction are outside day-to-day building tasks. Disaster recovery is one area where they are already proving their value. As mentioned, after California’s Pacific Palisades wildfires, for example, ABB Robotics worked with Cosmic Buildings to deploy autonomous systems that stabilized damaged structures and cleared debris, allowing human crews to begin rebuilding sooner. Similar systems could be vital after earthquakes, hurricanes, and industrial accidents, as they could repair structures, even dangerous ones like oil rigs, find survivors, extinguish fires, and clear contaminated areas, reducing the time it takes to restore critical infrastructure. In Figure 12 below, you can see one example from Japanese researchers that shows how different types of robots might assist in a tsunami or earthquake disaster:

Figure 12: Science Japan. Image of an application example of a disaster relief robot in the event of a large-scale earthquake or tsunami

Sustainability is another major area in which construction humanoids will improve the industry. First, the accuracy and efficiency of humanoid robots can dramatically cut down on wasted material. Studies show that robotic precision can reduce construction waste by 30%, while improving energy efficiency in completed buildings. This efficiency aligns with the growing emphasis on green construction and carbon reporting, making robots not just a cost-saving tool but a way to meet regulatory and environmental targets.

Globally, the potential is even larger. With infrastructure spending projected to significantly increase in the next decade, countries facing labor shortages are already looking at humanoid robotics as a way to scale. For repetitive tasks, such as assembling modular bridge components or tunneling, robots can be programmed once and deployed many times. Exporting robotic expertise and equipment could also become a major business opportunity for manufacturers around the world.

Playing to Win: Strategic Implications

The companies leading this transformation in the industry won’t just be the ones building robots. They’ll be the ones building data ecosystems alongside humanoid construction helpers. Every deployment of a humanoid robot generates valuable data, and firms that accumulate this data at scale will have a competitive advantage in bidding for projects, since they can prove faster timelines, tighter budgets, and improved safety outcomes with hard numbers.

This data-centric approach transforms construction from a fragmented, project-by-project business into a knowledge-driven industry where firms can leverage proprietary datasets for predictive modeling, benchmarking, and continuous improvement. Just as Tesla turned driving data into a strategic moat for autonomous vehicles, the contractors and robotics companies that control construction datasets will be able to offer superior forecasting, better cost control, and demonstrable safety advantages. This shift could reshape industry competition, with data-rich firms commanding premium pricing and attracting more favorable financing.

Reliability is a key differentiator. Construction is one of the few industries where robotic malfunctions could be fatal, so machines must meet exceptionally high safety and performance standards. Robotics companies that work closely with regulators, insurers, and industry associations to develop those standards will be able to provide the appropriate quality and safety level necessary for the industry.

Collaboration is also essential. No single company is capable of providing the full robotics solution for construction sites, which means partnerships between robotics developers, governments, heavy equipment manufacturers, software companies, and training organizations will be necessary. Some startups are positioning themselves not as robot manufacturers, but as integrators, helping construction firms choose and manage a fleet of robotics tools that work together seamlessly.

Conclusion

Humanoid robots in construction are not a future fantasy: they’re already being tested on worksites today, with evidence of improved safety, efficiency, and cost savings. With the global construction robotics market projected to grow to $25 billion by 2035, this sector will be moving from pilot programs to mainstream adoption.

Adoption rates will vary by region and company size, but the trajectory is unmistakable. Within ten years, major contractors will integrate humanoid robots into their standard operations, just like they now routinely use drones and BIM software. The transformation is inevitable.

For investors, unions, governments, and contractors, the critical question has evolved. It’s no longer about whether robots will reshape construction, but rather who will dominate this new reality, who will struggle to keep pace, and how rapidly the performance gap will expand between leaders and laggards.

The companies that emerge victorious won’t just solve technical challenges. Success demands mastery of the complete ecosystem: innovative financing that removes adoption barriers, comprehensive training programs that elevate worker capabilities, robust compliance frameworks that inspire confidence, and seamless integration with digital twins, supply chains, and project management systems. The smartest players will recognize that robots generate valuable data, not just productive labor.

The construction industry stands at a pivotal moment. For decades, the industry trailed manufacturing and logistics in automation adoption. That gap is rapidly disappearing. Humanoid robotics will reshape competitive dynamics just as dramatically as prefabrication, lean methodologies, and construction software once did. Companies that embrace this evolution will build faster, safer, and more intelligently. And more profitably.